At Applewood Joinery, we offer a variety of glazing options, each with its own strengths. In this piece, we’ll walk you through the different types of glass we use, the technicalities behind each unit, what they’re best suited for, and how to choose the right one for your home.

Double-Glazed

We use double glazing units very regularly, for doors and windows in the main. We use 24mm argon-filled double-glazed units as our standard which is available in both annealed and toughened glass. They’ve got a centre pane U-value of 1.2 W/m²K, which might sound technical, but it’s really just a way of measuring how well your windows retain heat. The lower the number, the better the insulation. In short, these units help keep your home warmer for longer, with less heat escaping through the glass.

Obscure Units

Satin obscure glass units are something we use very often and you can request multiple designs to be incorporated into your joinery. Many customers choose to personalise their doors with unique patterns making each piece truly bespoke. A lot of customers request for their glass to be sandblasted with their house number or name within.

Sandblasting is a technique used to create a frosted or textured finish on glass by blasting it with fine abrasive particles. It’s mainly used for decorative designs or to add privacy, giving the glass a soft appearance without compromising its strength.

Obscure units without a design are typically used to maintain privacy, perfect for bathroom windows or front doors, while still allowing natural light to flow through.

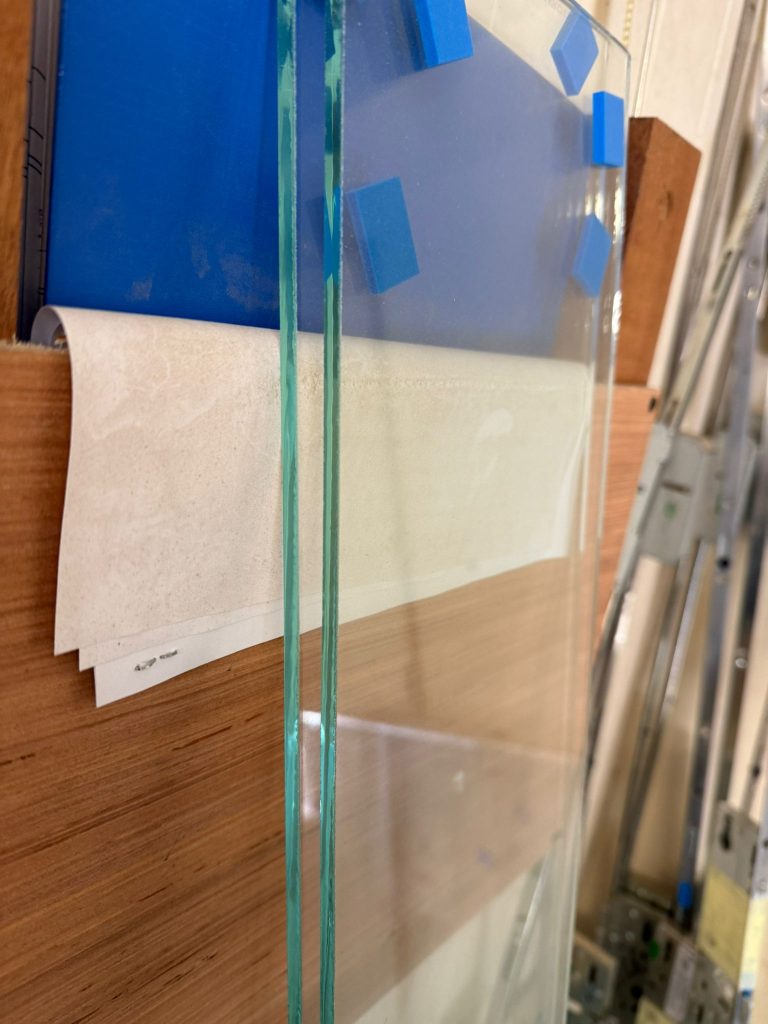

Single-Glazing Units

Many of our customers request that their windows and doors have single glazing units installed in them.

With no additional panes or coatings, single glazing allows more natural light and clarity. This is important if you would like to keep your home bright.

Single glazing is available in a range of thicknesses, most commonly 4mm, 6mm, and 8mm. Each size offers a different balance of strength, clarity, and weight, depending on where it’s being used.

Lots of our customers are wanting joinery for listed buildings and single glazing is very popular for this. Many listed buildings were originally fitted with single glazed windows. These contribute to the building’s character and heritage value, and most people would like to keep the look.

In addition, any changes to windows in a listed building typically require Listed Building Consent (LBC). To preserve the building’s architectural integrity, single glazing is often mandatory for replacement windows, ensuring they remain consistent with the original historic design.

Single glazing has a U-value of 5.8 W/m²K, which is relatively high indicating poor heat insulation. More heat escapes through the glass, making it less energy-efficient than modern alternatives. This reduced thermal performance is one of the key drawbacks of single glazing.

Most older buildings still use single-glazed windows, these include churches and old heritage sites. We get a lot of requests to make bespoke windows for these properties, and it’s something we really enjoy. It’s about keeping the traditional look while making sure the quality and finish meet today’s standards.

Toughened Units

We primarily use toughened panels of glass in all of the doors that we manufacture. BSEN12150 is the legal British standard for making thermally toughened safety glass and that is required for doors. Toughened glass is also required (by law) in windows that are 800mm or lower from the floor or if the window is within 300mm from a door.

Toughened glass usually has a faint stamp or marking in one corner. It might say “Tempered” or “Toughened,” or just show a code from the maker.

Toughened glass has shatter protection, this means that when it is broken, it crumbles into smaller blunt fragments. This reduces risk of injury massively and makes it safer in general.

Toughened glass is also 5-6 times stronger than your standard glass units. This means they resist weather much better and can survive for longer due to their strength and durability.

There are a few downsides to toughened glass units these include, any attempt to cut, drill, or edge it post-process will cause toughened glass to shatter. All shaping must be done beforehand.

Toughened glass can suddenly shatter all at once, especially if it’s struck near the edge or at a weak spot. The tempering process is more complex and energy-intensive than standard glass production, making toughened glass more expensive.

Roof Glass

We occasionally use roof glass at Applewood Joinery, mainly for conservatories and orangeries. These glazed sections are often referred to as skylights or rooflights, designed to bring natural light in from above and open up the space.

Roof lanterns are usually pyramid shaped, with angled glass that helps guide rainwater down and away from the structure. The glass is always toughened for strength and safety, and often tinted depending on the project.

We also offer self-cleaning glass on request. It comes with a specialist coating that reacts with natural daylight to break down and loosen organic dirt. When it rains, the water spreads evenly across the surface, forming a thin film that helps wash away debris and keeps the glass looking clear with fewer streaks.

Some conservatory roofs and roof lanterns have solar control glass installed. Solar control glass is a type of glazing designed to manage how sunlight enters a building. It helps reduce heat build-up, glare, and UV exposure, making spaces more comfortable without blocking natural light. The lower the G-value, the less heat gets through the glass. It’s a great choice for roof lanterns or garden rooms that get loads of sun, keeps things bright and comfortable, without turning the place into a greenhouse.

Comments

2 responses to “All Things Glass”

[…] ALL THINGS GLASS TIMBER TALK TIMBER OVER UPVC FIND YOUR FINISH WHAT MAKES OAK SPECIAL BEHIND THE SCENES FITTED UNITS BESPOKE WINDOWS BESPOKE JOINERY FRONT DOORS STAIRCASES UNDER STAIR STORAGE ←Previous: All Things Glass […]

[…] doors in west wellow why we love softwood garage doors where craft meets care heritage joinery all things glass timber talk timber over upvc find your finish what makes oak special behind the scenes fitted units […]